Why Is It Important To Machine Manufacture Metals?

The concept of machining has evolved manifold. Earlier, factories and industries would hire laborers and demand everything to be done manually. The introduction of the machining manufacture process, as a result of advancement in science and technology, has changed the entire concept of how these factories and industries operate their business.

Why Is It Important To Machine Manufacture Metals?

The use of machine manufacturing has benefitted the metal industry the most. Cutting a piece of metal or other raw material into different shapes and sizes has become quick, easy, and effortless. Different types of machine manufacturing have been introduced worldwide, all of which serve many benefits to the owners and employees.

Here is everything to know about the importance of machine manufacturing, especially in the metal industry:

Why Is It Important To Machine Manufacture Metals?

Less Human Labor

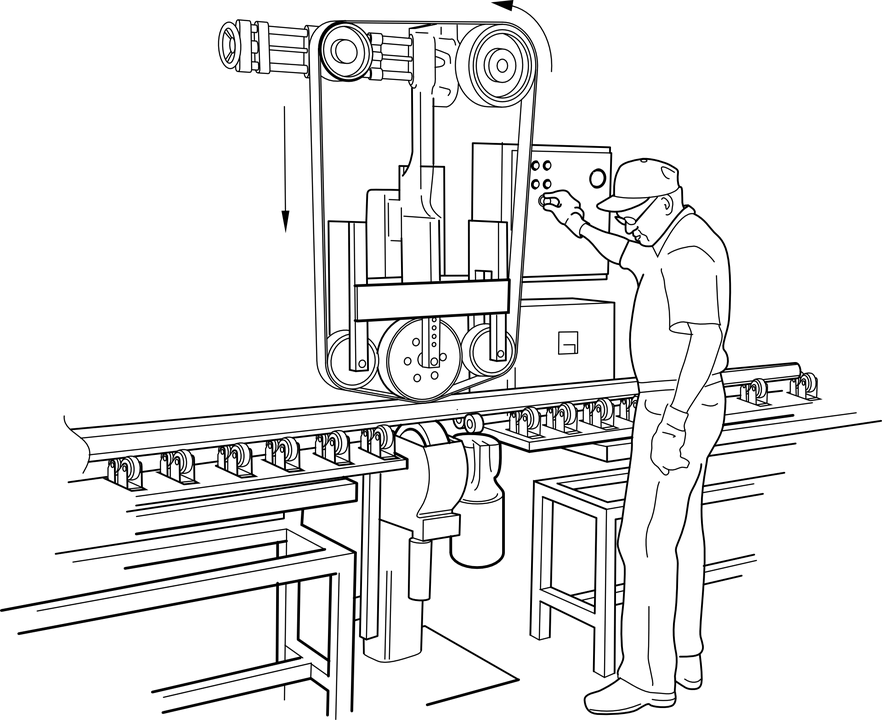

The development in technology has automated the entire manufacturing industry. The process is majorly controlled by machines, computers, and robots. It has also cut down the production cost and eliminated human labor.

The workers at the factories and industries do not need to work endlessly and tire themselves anymore. The introduction of machine manufacturing has led to minimal supervision as well as oversight for maintenance purposes.

High Production Than Before

The use of different kinds of machines in the metal industry has led to high production. The various machines present in the factories take care of the massive amount of work such as drilling, milling, finishing, spinning, and others. As a result, the process becomes faster and more effective.

Production of Identical Products

Cutting metals manually is not easy. Moreover, no two products come out to be identical when you cut them using different tools and equipment. On the other hand, when you use machines for cutting metals, the results are homogenous.

Machine work leads to very little or no scope of errors whilst maintaining the quantity and quality of the work. Consequently, the products become more marketable because of their high quality and supremacy.

Whether you are focusing on low volume tooling or high mass production, machining has become a staple in ensuring products are alike to keep output efficient and quality on point.

Reduced Efforts and Increased Profits

While the laborers and employees save themselves from handling the process manually, the owners also benefit because faster work and quality results increase their profit.

Buying high-end machines may be an expensive investment at first, but at the same time, you cannot turn a blind eye to the benefits that it will offer in the long run. A good-quality, error-free machine always yields the best production results.

Enhanced Efficiency

Machining is the best way to increase the efficiency of metals. When different metals go through machine manufacturing, they are fitted with internal quality assurance detectors. It brings efficiency in terms of increasing production speed and ensuring a perfect use of the raw materials.

Besides this, machining is considered an incredible way of ensuring high-level standards of metal part fabrication. Improved results, reduced costs, and minimal waste are other perks of using machines at your factory.

Different Machining Processes – An Overview

Machining processes can be categorized under three sections – turning, milling, and drilling.

Turning is the first phase that uses a cutting tool to remove the metal from a rotating workpiece. Afterwards, milling uses a rotating cutting tool to remove the metal from a stationary workpiece. After that, drilling uses a drill bit to cut a threaded hole into the workpiece. Other machining stages include various processes such as deforming, burnishing, polishing, and others and vary in workpieces.

Takeaway

The above-listed pros also highlight the importance of machine manufacturing in the metal industry. Machine manufacturing has also become the need of the hour if you want your business to survive and excel in this cut-throat competition. As a factory owner, it is vital to incorporate the use of machines to entertain long-term profits.

Founder Dinis Guarda

IntelligentHQ Your New Business Network.

IntelligentHQ is a Business network and an expert source for finance, capital markets and intelligence for thousands of global business professionals, startups, and companies.

We exist at the point of intersection between technology, social media, finance and innovation.

IntelligentHQ leverages innovation and scale of social digital technology, analytics, news, and distribution to create an unparalleled, full digital medium and social business networks spectrum.

IntelligentHQ is working hard, to become a trusted, and indispensable source of business news and analytics, within financial services and its associated supply chains and ecosystems