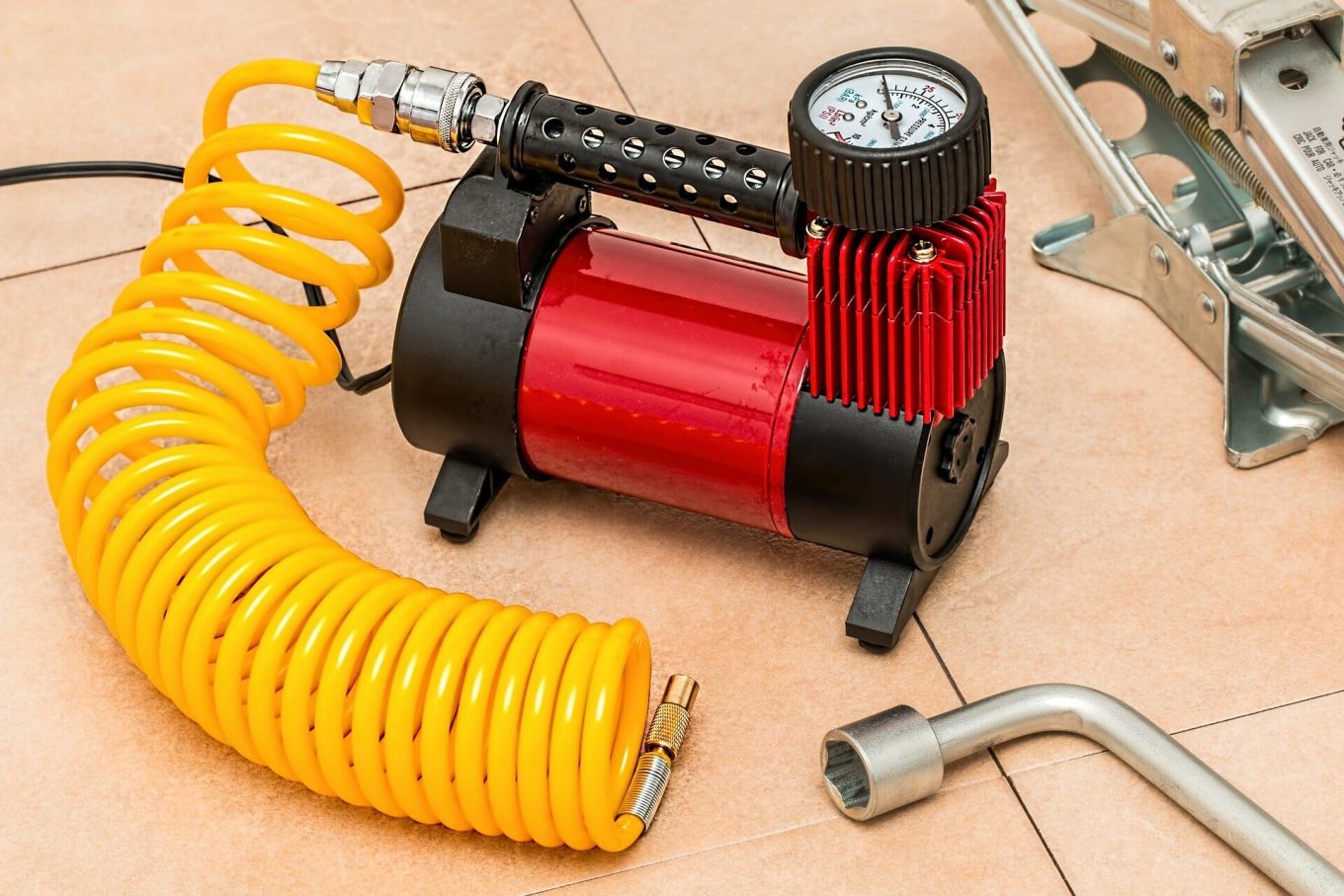

Although compressors are commonly found at construction sites, due to the elemental role they play, they remain important for many people across various fields. In fact, with the help of the CDH group, compressors are found to be exigent in advancing essential day-to-day operations, such as with automobiles, diving, the energy sector, and many more. On top of that, some people even find a use for them in their personal lives, which include inflating tires and enhancing the performance of a refrigerator. However, seeing as they come in various shapes and sizes, each being intended for certain purposes, it is important to be able to distinguish between each. If you are planning on investing in a quality air compressor for your business, then better read on to learn more. You can also check for guides and reviews on the most popular air compressors in the market on BestOfMachinery.

What is a Compressor?

First, it is important to gain a general idea of what a compressor is. They are mechanical devices that make increasing the pressure of gas possible. This is done by reducing the volume. In fact, due to compressors sharing a few similar characteristics to pumps, many have drawn parallels between both, seeing as each is capable of increasing the pressure of fluids, as well as transporting them through pipes. However, pumps generally do not reduce the volume of a gas and those that do are not as efficient. Typically, compressors are made out of two components, the compressing mechanism, and a power source. The compressing mechanism mainly consists of a piston and vane, while there are more parts to it. As with all mechanical equipment, for Compressor Service and Repair, it is important to look for factory-certified technicians to guarantee that the job is done correctly and efficiently.

With that said, here is all that you need to know about the types of compressors and their uses.

Reciprocating Compressors

Perhaps the most common type of compressor to be found in mobile purposes is a reciprocating compressor. Also referred to as piston compressors, these machines are prevalent in the markets. Reciprocating compressors are a type of positive displacement compressor that can offer a dramatic horsepower range. The mechanism of a reciprocating compressor involves pumping air into the air chamber of the machine, which then goes to reduce the volume in the chamber.

Reciprocating compressors are found to work similarly to an internal combustion engine, but inversely in some ways. The machine includes pistons, cylinders, crankshafts, valves, and housing blocks. Moreover, reciprocating compressors are found to be the most efficient compressor and are usually larger. Furthermore, this type of compressor finds usage in households, job sites of all sizes, automobiles, and in petroleum applications. However, they can come at a steep price, which may not suit most people. The compressor wizards at Ablesales explain that for household purposes, opting for an electric compressor can come at more than half the price of other compressors, like diesel air compressors and petrol compressors. Also, seeing as the average household usage is usually kept to a minimum, a 240 Volt 100 Liter electric compressor should sufficiently tend to your needs.

Rotary Sliding Vane Compressor

Although it belongs to the category of positive displacement compressors, rotary sliding vane compressors work in a slightly unconventional manner, since the rotor is arranged within the stator. Moreover, the rotary sliding vane compressor features a pump that is made out of a rotor, 8 blades, and a stator. As soon as the compression is activated, the volume immediately goes from the maximum, which is at the intake port, to the minimum that is at the exhaust port.

The rotary sliding vane compressor uses oil injections to keep the machine lubricated, as well as maintain lower temperatures. Additionally, the oil goes to seal the vanes. This increases efficiency, which can push it as high as 90%. Furthermore, rotary sliding vane compressors can either be stationary or portable, while you can also choose between internal combustion engines and electric motors. Ideally, these machines are best suited for a wider range of applications, across several industries. This can include things like drying chemical products, sterilizing medical instruments, and operating pneumatic tools.

Rotary Screw Compressor

Another type of positive displacement compressor, rotary screw compressors focuses on filling voids with air. This happens between two helical screws, where the gas becomes entrapped. Subsequently, the screws begin turning, which reduces the volume of gas caught in the chamber. Naturally, the reduced volume will increase the air pressure. Furthermore, most rotary screw compressors will require lubrication. For this reason, they will usually inject oil. Moreover, the oil can also help cool down the machine, while also sealing the areas from which oil can leak.

Typically, rotary screw compressors come in the standard variant, which features two screws. However, designs with three or just a single screw do exist. Moreover, they include a simpler and compact structure, which boasts higher efficiency and very little vibration. Additionally, rotary screw compressors include fewer components and can operate at different and adjustable speeds. They are usually used in large industrial areas, while they can also find other applications, like with households. However, in order to maximize its efficiency, its best use comes in applications that focus on a continuous air demand, such as with automated manufacturing systems and food packaging plants.

Centrifugal Compressors

Unlike the other compressors, centrifugal compressors are not part of the positive displacement compressor family. However, this does not render centrifugal compressors as a lesser machine. The way it works is by utilizing the impellers to accelerate the air into extremely high speeds, which can then be decelerated by using the diffuser. The machine is typically the largest compressor and it offers high rates of efficiency.

The uses of centrifugal compressors primarily involve stationary and continuous application, with the most typical relating to industries like natural gas processing plants, petrochemical plants, and oil refineries. Moreover, centrifugal compressors are also used in refrigerators and air conditioners. Though, this commonly involves having a screw compressor included alongside. Additionally, this type of compressor has found popular use in snowmaking operations.

All in all, these 4 different types of compressors are the most common ones used today, having found a great many uses across several industries. They each offer a variety of uses, with some being specific to a certain type of operation. However, they have also managed to find just as many uses in our homes, with things relating to our personal lives, such as refrigerators, air conditioners, and the bothersome task of inflating tires. But remember, if you are looking to get a compressor for personal use, an electrical one will not cost nearly as much as others.

Founder Dinis Guarda

IntelligentHQ Your New Business Network.

IntelligentHQ is a Business network and an expert source for finance, capital markets and intelligence for thousands of global business professionals, startups, and companies.

We exist at the point of intersection between technology, social media, finance and innovation.

IntelligentHQ leverages innovation and scale of social digital technology, analytics, news, and distribution to create an unparalleled, full digital medium and social business networks spectrum.

IntelligentHQ is working hard, to become a trusted, and indispensable source of business news and analytics, within financial services and its associated supply chains and ecosystems